Pro-Cut PFM X9 On-Car Brake Lathe

Product Description

INTRODUCING THE PFM X9 DRO HIGH-PERFORMANCE BRAKE LATHE FROM PRO-CUT

The PFM X9 brake lathe combines Pro-Cut’s best-existing technologies, like the patented PFM one-button computerised compensation system and a 4-wheel, 4-axis, fully adjustable trolley. It combines them with a rigid new X-frame lathe chassis, powerful belt-driven high-torque drivetrain, and super bright 6 LED light to give you a clear path to higher profits! The X9 is digitally expandable to an optional G2X system. All X9’s come with Pro-Cut’s famous DRO display, including live run-out, productivity tracking, and lathe diagnostics.

The PFM X9 uses the same adapters and cutting head as the older 9.2 model but has been designed with a more robust drivetrain, body design, and LED lighting.

FITS ON MANY VEHICLES

The Pro-Cut adapters will connect you to almost any vehicle on the road today, giving you the power to turn even stiff all-wheel drive and truck axles. Plus, Pro-Cut’s simple set-up is the same, from compact cars to dual-wheel vans.

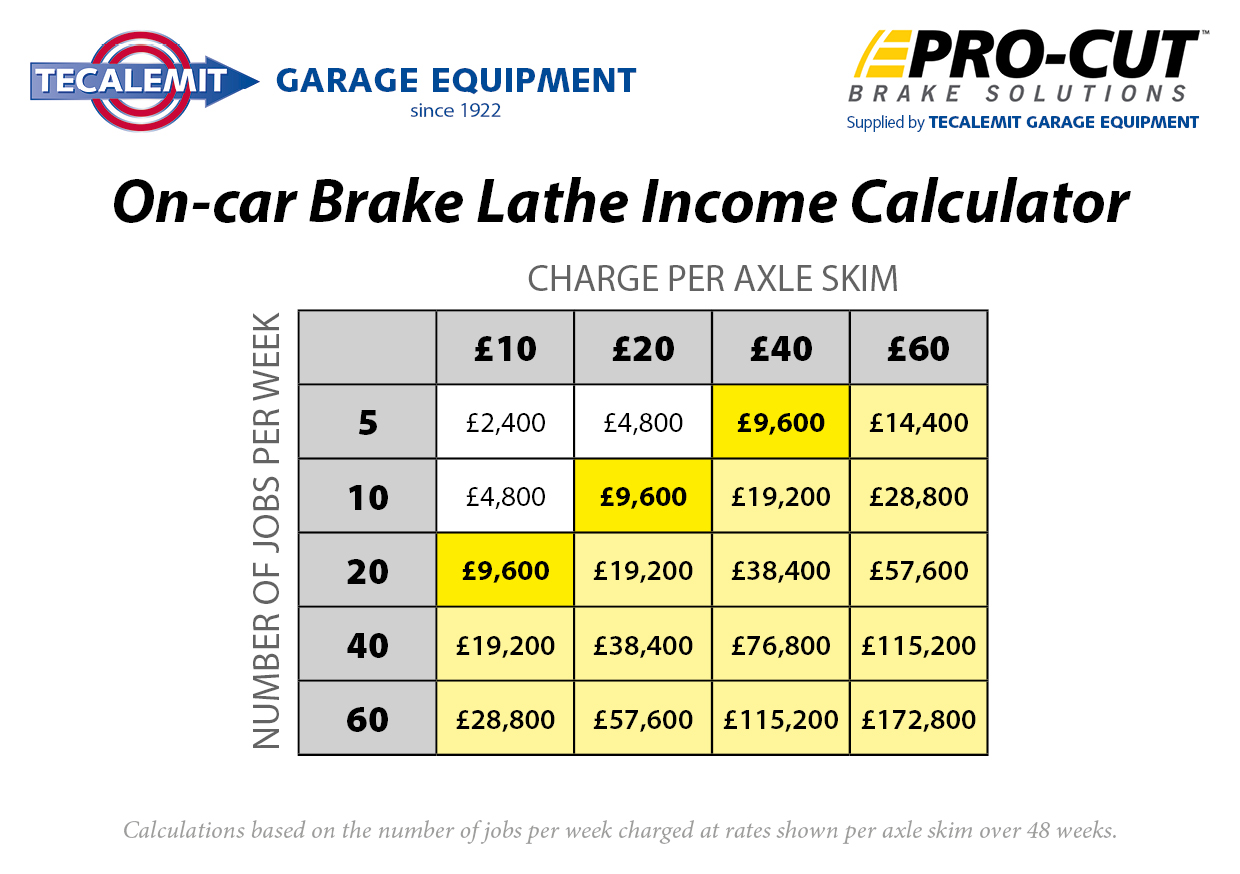

MATCHED DISCS AS A NEW REVENUE SOURCE

Tyres need to be balanced, wheels need to be aligned, and discs need to be matched. Adding disc matching to your service offerings adds a new revenue source.

MACHINE A DISC IN UNDER 10 MINUTES WITH OR WITHOUT A LIFT

2-post, 4-post, scissor, or even no lift….it doesn’t matter! Pro-Cut’s fully adjustable trolley allows you to roll up and mount your Pro-Cut lathe confidently. Once set up, you can resurface a brake disc in under 10 minutes and a whole car in less than an hour.

Why choose an On-Car Brake Lathe?

Some people may consider brake disc skimming an old-fashioned practice that stopped many years ago. Not true. Today’s on-car brake lathe technology, where Pro-Cut is the world leader, enables workshops to efficiently and accurately resurface brake discs offered as a supplementary service which can make additional profits.

Resurfacing brake discs should happen when:

- Brake pads are changed, but new discs are unnecessary, which frequently happens. There is no bedding in, and your customer has perfect brakes as they leave your workshop.

- There is evidence of brake vibration due to Disc Thickness Variation (DTV) or excessive run-out. For this problem, using an on-car lathe is the only permanent solution.

- Discs are suffering from corrosion, resulting in poor braking performance or imbalance. This can also be unsightly, particularly on used cars in a showroom or forecourt.

- The brakes are noisy.

- When fitting new pads to ‘lipped’ discs, ‘brake squeal’ can result. This is fixable by skimming the discs to remove lips and producing perfectly flat disc surfaces.

To view some of the previous Pro-Cut models in action, see our Video Library.

Key Features

- Patented one-touch lateral run-out compensation

- DRO “Live” digital computer display

- Computer tracking for ROI calculation

- 4 Standard adapters included

- Speed-lock cutting head

- Rigid X-frame lathe body for increased durability

- Increased spindle bearing separation for smoother cuts

- Gear reduction transmission and cog belt drive for increased torque and longevity

- 6 LED On-board work-light for improved visibility

- 4-Wheel, 4-Axis adjustable trolley

What's Included

- PFM X9 DRO brake lathe

- Speed Lock cutting head

- Super bright 6 LED work-light

- 4-Wheeled disc trolley

- 4 hub adaptors

- Silencer and cutting tips

- On-site installation

- Initial training

- 12 months warranty