Down near London’s Mile End, Sayeed had established a successful car servicing operation. MOTs formed a significant part of Sayeed’s customer requirements. However, like many smaller garage operations, outsourcing MOT tests to a local DVSA-approved MOT centre wasn’t working for him. Whilst this fulfilled Sayeed’s customer offer, the administration and additional work are time-consuming, expensive and disruptive.

Sayeed’s current servicing and repair unit could not accommodate an MOT bay, so the search for new premises began. After locating a suitable unit, he could proceed to the MOT application and creation process.

“Sayeed wanted to utilise a 4-Post lift for the MOT bay and selected an SF/9254 in a recessed format”

Sayeed knew that Tecalemit’s Bernard Gravillis had recently completed a pit-based Class 4 MOT centre over at Campbell Road Garage. There was no hesitation to contact Bernard and commence creating an MOT test capability in this new location.

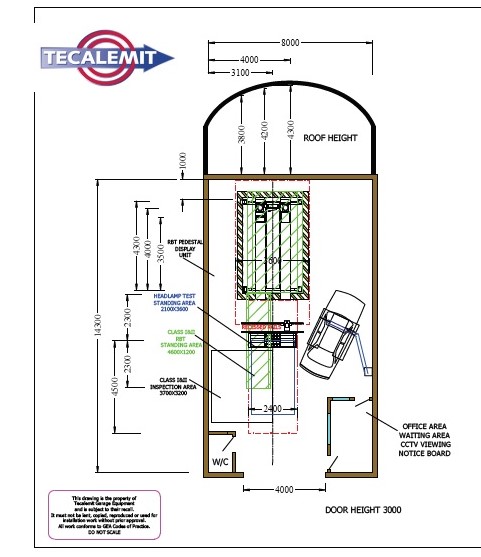

Sayeed wanted to utilise a 4-Post lift for the MOT bay and selected an SF/9254 in a recessed format. The new unit was located in a railway arch of quite generous proportions. This enabled the roller brake tester to be positioned close to the vehicle lift, utilising the lift as part of the brake test standing area. The brake tester complies with the latest specifications, which mandate its connection to the DVSA MTS for the automatic transmission of brake test data. An ATL brake tester weighs the vehicle and automatically calculates the brake force results, simplifying the administration of the MOT tester.

“The Agreement In Principle (AIP) for the new MOT test lane is a major milestone in the process”

Sayeed also chose to incorporate Class 1 & 2 motorcycle MOT testing into the Class 4 bay. This meant the headlamp beam tester would be installed in a drive-over configuration, with recessed rails, between the brake tester and the vehicle lift. This would enable the headlamp tester to be used for Class 1 & 2 plus Class 4 MOT tests.

A combined emission tester would also be configured to house the control unit for the brake tester, further saving floor space within the building by utilising the same roller cabinet, printer and display screen.

Bernard prepared the proposed equipment layout drawing to support Sayeed’s DVSA VT01 application. The Agreement In Principle (AIP) for the new MOT test lane is a major milestone in the process. With it, Sayeed could schedule civil work to prepare the floor recesses for the 4-Post lift and brake tester. The builder must be fully conversant with the civil work dimensions and the required cable ducting channels. Bernard always meets with the building contractor to ensure the equipment’s correct integration into the groundwork plans. This ensures the proper positioning of the control cabinets and the correct power supply points.

“Sayeed chose a 3-Year Calibration, Servicing & Warranty package for the MOT equipment”

Coupling with the bay, Sayeed picked a recessed short-platform scissor lift for MOT repair work. To ensure it didn’t interfere with the MOT bay, Bernard also marked out the floor for the building contractor.

To cater to the MOT bay’s ongoing operation requirements, Sayeed chose a 3-Year Calibration, Servicing & Warranty package for the MOT equipment. This would provide peace of mind for the next thirty-six months, ensuring that mandatory calibrations are automatically scheduled whilst delivering lower operational costs.

A decelerometer with DVSA connectivity plus viewing mirrors, a brake pedal depressor, and an ancillary site & tools pack completed the suite of Automated Test Lane (ATL) equipment, enabling Sayeed to undertake one-person testing.

The unit’s transformation is fantastic, from a derelict unit to a DVSA-approved MOT testing facility. The Tecalemit team always looks beyond the ‘here and now’ to the art of the possible.

Tecalemit would like to thank Sayeed for choosing Tecalemit equipment for his new MOT centre. We wish him well with his business plans.

To benefit from the experience of our Workshop Equipment Specialists, call Tecalemit on 01752 219111 and turn your MOT plans into reality.