Taylor’s Auto Electrical is a specialist company in Aberdeen that focusses on repairing vehicles’ electrical and fuel injection systems. The company began in Aberdeen in 1950 under the name C V I Farquharson, a short walk from the train station. Since the start, Taylor’s Auto Electrical has been a full Bosch Service agent and is one of their oldest agents in Scotland. In 1974, Charlie Taylor purchased the company from Mr Farquharson upon his retirement.

In 1988, Taylor’s was bought by Dingbro Ltd., relocated to larger premises at Lang Stracht and adopted its current name. Today, the company has a team of over 20 staff members and has invested heavily in staff training and specialist test equipment to work on all makes of cars, trucks, buses, and motorhomes. Taylor’s Auto Electrical prides itself on being able to diagnose and repair all kinds of vehicle problems, including the most complicated electrical issues. Taylor’s also maintains a large inventory of spare parts for repairs.

Recently Taylor’s took the opportunity to overhaul their workshop and approached Tecalemit for assistance. Not only did they want to replace several of their existing lifts, but the team also wanted to relocate a 4-post lift to create a more efficient layout. Working with Jim McDermott, Tecalemit’s Sales Manager for Scotland, they looked at the options and decided on three SF/9235/EVR EV-ready lifts and a larger, 5.0t 2-post lift. This combination of lifts would give them the flexibility and versatility to handle the range of vehicles they are currently working on.

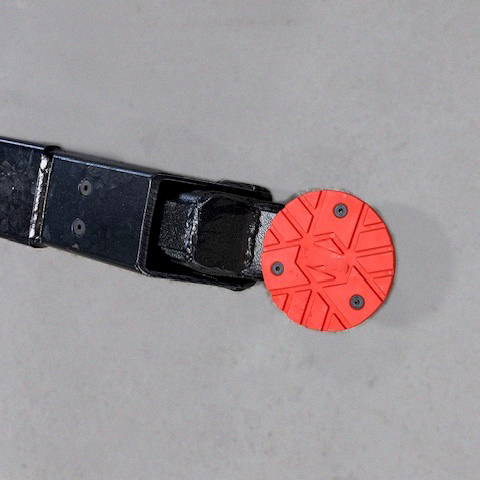

The SF/9235/EVR lifts were particularly interesting to the team at Taylor’s due to how they have been designed to lift EVs safely. This innovative 2-post lift is ideal for anyone who wants to set up an adaptable workshop. The low-profile arms offer incredible flexibility, making the lift suitable for lifting many vehicles, from small city cars to sports cars, including the many modern electric vehicles. What makes the lift special is the EV lifting forks that make battery repair work and servicing of EVs much more accessible.

In addition to the EV-ready lifts, Taylor’s chose an SF/9025 5.0t, heavy-duty 2-post lift suitable for lifting larger, commercial-based vehicles. The symmetric arms can easily lift long-wheelbase vehicles, and the drive-through width of 2.7m accommodates most LGV vehicles. And, like the EV-ready lifts, it benefits from a baseless design with a clear floor between columns. This design allows equipment to be easily positioned underneath a vehicle without being dragged over a raised base frame. The workshop redesign was completed with the addition of a new cased air hose reel to each of the lifts.

All that remained was to arrange the installation of the equipment, but Taylor’s wanted to stay open during this transition. Tecalemit were happy to accommodate and devised a schedule that minimised disruption to the business. Les Clark, Taylor’s Branch Manager, spoke about the installation, “The workmanship was second to none, and our team of technicians were able to carry on with their day-to-day duties with next to no disruption whatsoever. Tecalemit’s team of technicians were very accommodating and worked around our lads to suit us, which means a lot, it made planning our workload simple, and we kept a steady flow of work coming in the door.”

We want to thank the team at Taylor’s for choosing Tecalemit equipment as they continue to build on over 70 years of success and prepare for the future of motoring.