Haweka QuickPlate

Product Description

The Haweka QuickPlate® System allows tyre shops to replicate the on-car wheel clamping method during the wheel balancing process.

The aperture on the front of alloy wheels is designed to hold the centre cap, not a wheel balancer cone, although this is the approach used by many tyre shops.

Using Tecalemit Haweka ‘DuoExpert’ Expanding Collars and ‘QuickPlate®’ Variable Flange Plate Adapters allows the vehicle manufacturers’ wheel clamping method to be replicated during the wheel balancing operation. On a vehicle, the wheel is centred using the hub spigot, which fits the rear face of the alloy wheel. The wheel is clamped to the vehicle hub using nuts or studs.

This ensures a more accurate balancing result whilst also preventing the possibility of marking the front face of the alloy wheel around the centre cap aperture.

Haweka QuickPlates® features a continuously adjustable stud hole pattern (PCD) from 95 – 182mm for all 3, 4, 5, 6 and 8-hole rims. No time-consuming searching for the correct stud hole pattern.

Changeable spring-loaded stud caps can be selected for different rim types.

A ProLock-System, for stud hole pattern (PCD), enables the Quickplate to be set for the wheels requiring balancing, enabling fast and repeatable wheel balancing.

The Quickplate® is also futureproofed. Its adjustable capability will fit vehicles with yet-to-be-released PCDs

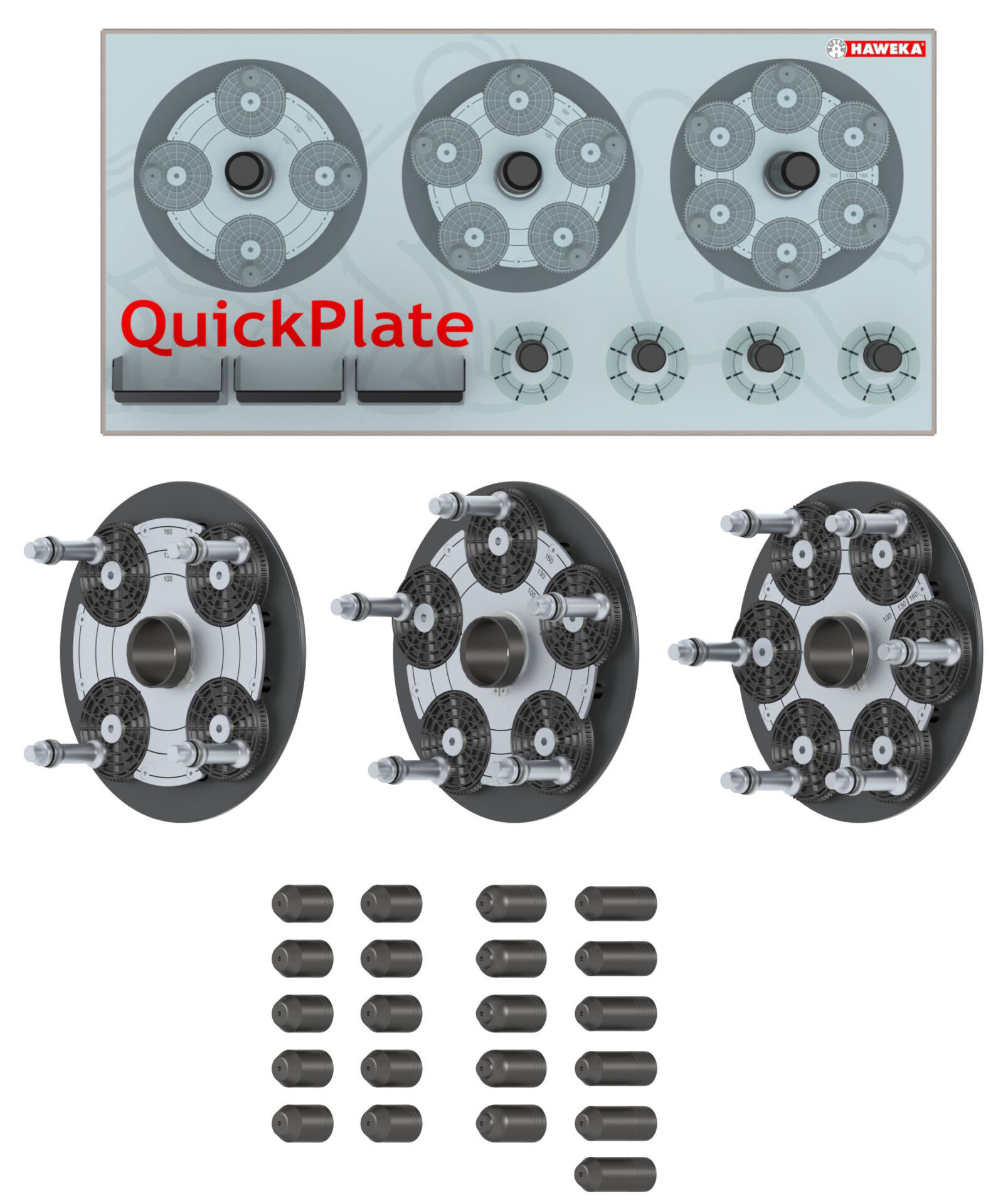

The following Quickplates® and sets are available:-

- Quickplate® 4-Holes HAW/249012400

- Quickplate® 5-Holes HAW/259012400

- Quickplate® 6-Holes HAW/269012400

- Set of 2 Quickplates® (4 & 5 Hole) With Wall Mount System HAW/210400005

- Set of 3 Quickplates® (4, 5 & 6 Hole) With Wall Mount System HAW/210400001

Quickplate® Caps Can be purchased individually or in sets

- HAW/273e008025 long taper- 58mm long total length 100mm diameter 22.5mm

- HAW/273e008023 narrow taper – 55.6mm long total length 97.6mm diameter 19.0mm

- HAW/273e008007 round head – 48mm long total length 90mm diameter 24.5mm

- HAW/273e008009 Land/Range Rover – 38mm long total length 80mm diameter 34.0mm

Note total length is when the QuickPlate cap is on the QuickPlate stud