Down in London’s E3, Kutub Uddin had created Campbell Road Garage, a multi-disciplined vehicle service and maintenance centre based in Bow close to the City and Canary Wharf.

Specialising in Mercedes and other prestigious vehicles, Kutub had several years of experience looking after retail and fleet customers. MOT testing was essential to the Silver Arrows’ customer proposition, with all MOT testing being outsourced to local providers.

Kutub had long desired to bring MOT testing’ in-house’ to reduce the associated downtime and costs of running cars back and forth to other testing providers.

“Tecalemit provides inspection pit MOT testing solutions to overcome height restrictions”

The workshop had significant height restrictions, being a railway arch, with a limit on the headroom and no possibility of utilising a vehicle lift. Fortunately, Tecalemit provides inspection pit MOT testing solutions to overcome height restrictions.

Kutub came to Tecalemit Garage Equipment and was put in touch with Bernard Gravillis, Area Sales Manager for London and the South East. Bernard has created hundreds of Tecalemit MOT bays over the last twenty years and has subsequently dealt with just about every challenge imaginable.

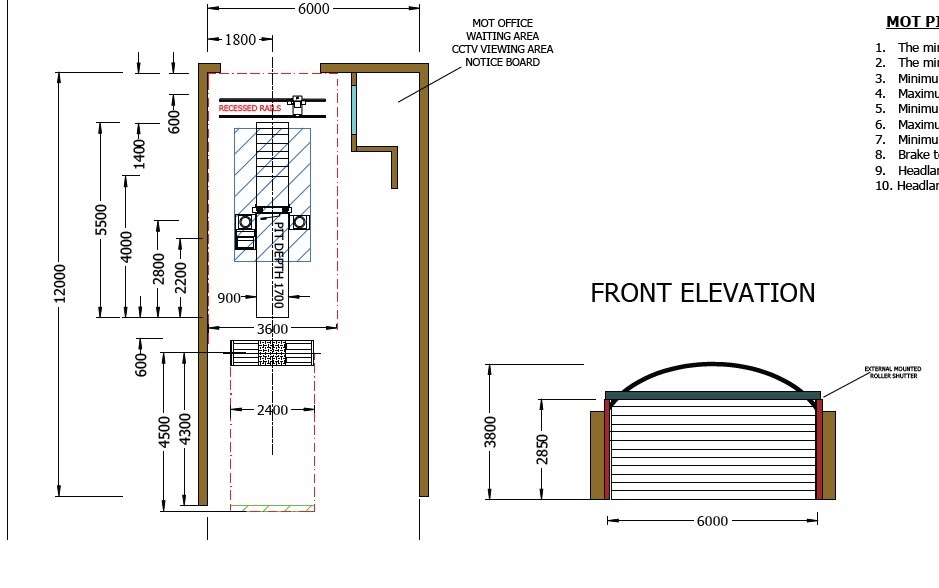

There was a requirement to retain drive-through access to the back area of the workshop. This means positioning the MOT inspection pit and the headlamp beam tester to maintain the DVSA’s mandated standards whilst still providing all-important access to the rear of the workshop. For this location, down in Bow, a pit-based solution was the only viable option, but even that required a lot of consideration and planning.

“Incorporating the control units in the pit wall would reduce the space required on the workshop floor”

Then there was the method of pit construction to consider. The plan was to use a brick-built pit instead of a Tecalemit pre-fabricated steel unit. This would need careful design to incorporate the appropriate recesses in the pit wall to accommodate the control unit for the Tecalemit DE/7361 hydraulic play detectors that would support one-person testing in conjunction with a Tecalemit Automated Test Lane (ATL) brake tester. Incorporating the control units in the pit wall would reduce the space required on the workshop floor. This allows the pit to be tucked as far to the left of the workshop as permitted by the DVSA.

The drive-through provision would require recessing the DE/7288 headlamp tester rails into the workshop floor. It also needs a location that did not prevent access to the rear of the workshop when not in use.

With all of the requirements discussed, Bernard could produce a layout drawing to support the DVSA VT01 application. With Bernard’s experience with MOT design, the Agreement In Principle (AIP) was obtained from the DVSA on the first application.

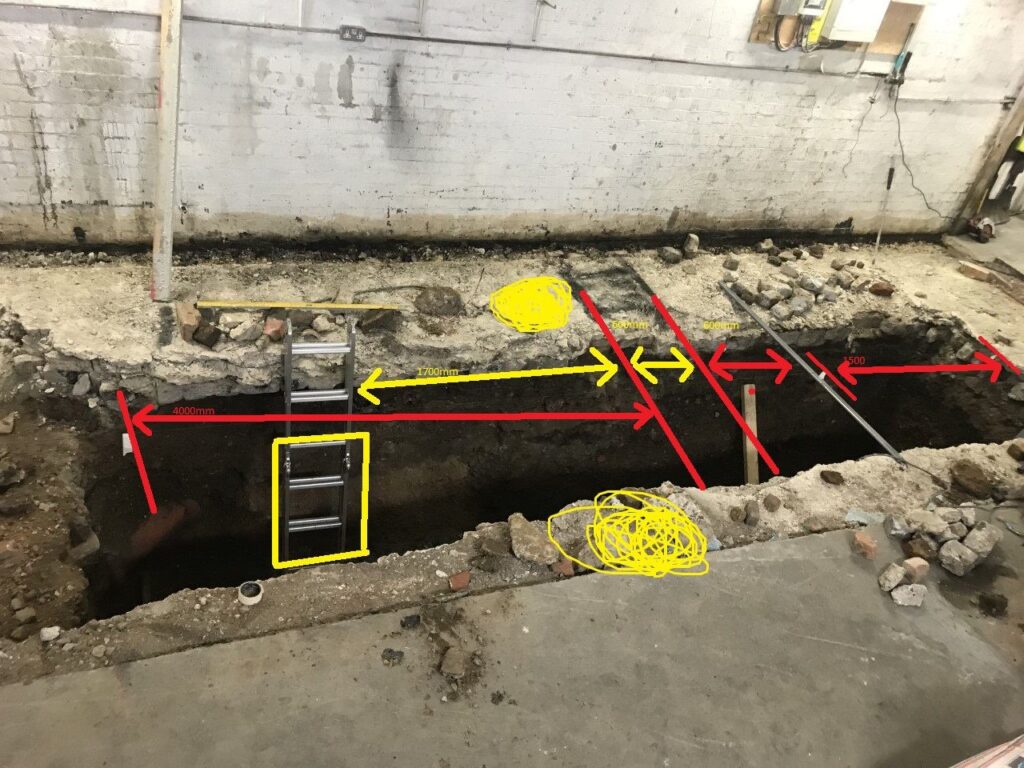

This enabled the excavation for the pit build to commence. It would be a big dig, with a substantial amount of material to remove. You have to consider the cable routing and ducting to ensure correct positioning at the design stage. Bernard supported with comprehensive measurements through the entire process, even overlaying dimensions onto a photograph of the excavation. This helped reassure Kutub that the excavation was sufficient to accommodate the DVSA-required dimensions.

“The pit design utilised some steel angle iron to form the top edge”

The construction of the brick pit could commence with the recess formation for the Class 4 brake tester. Kutub took Bernard’s advice and utilised a recess edge frame for the brake tester. This makes it easier to prepare the recess to exact dimensions whilst providing metal edge protection to the concrete recess. The pit design utilised some steel angle iron to form the top edge of the pit. This provides a durable surface on which to run the Tecalemit SS/8872 jacking beam. Once painted yellow, this would match the brake tester and the Tecalemit DE/7361 play detector recess frames.

Finally, after several weeks of hard work, the civil work was complete, and the equipment installation could commence. Kutub had selected the hi-visibility LED display for the Tecalemit DE/9419 brake tester. This unit is easy to read in brightly lit workshops and is a feature unique to Tecalemit brake testers.

A Tecalemit MDS/ATL combined emission tester also doubles up as a control centre for the DVSA-connected brake tester, providing further savings to the amount of surface-mounted MOT equipment.

Kutub also thought about the ongoing running of the MOT bay, choosing to incorporate a Tecalemit 3-year care package. This covers the calibrations and maintenance whist providing a 3-year warranty for the MOT equipment, ensuring peace of mind.

We thank Kutub for choosing us for his new MOT bay, and we wish him well with his business plans.

To benefit from the experience of Bernard Gravillis and his fellow Workshop Equipment Specialists, call Tecalemit on 01752 219111 and turn your MOT plans into reality.