The creation of a brand-new workshop facility can take many months, from acquiring a new site location to planning permission and the subsequent civil and building work. Add the requirement to incorporate DVSA-approved MOT testing into the mix, and the project complexity increases significantly.

What might be classified as a reasonably ‘level floor’ may take on a different set of requirements when the run-up ramp into the workshop bay is to be used as part of the brake test standing area for the MOT bay. Not a problem, provided the team at Tecalemit is involved in the building design and specification stage. Considering the DVSA-mandated standards at the workshop design stage can save significant time later in the project.

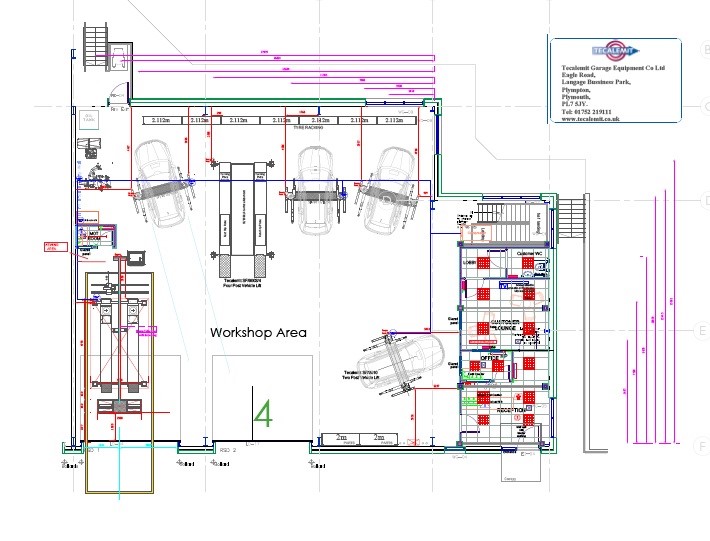

Here the team at Tecalemit look at the creation of a multi-bay vehicle workshop facility incorporating a Class 4 MOT bay using a recessed bay configuration for the Tecalemit SF/9254 MOT Lift and Tecalemit DE/9419 DVSA Connected Brake Tester.

Ian Blackett from Tecalemit Garage Equipment has worked with numerous site developers and builders to create such workshops from scratch.

“The earlier we are involved, the easier it is for all parties. Beyond the mandatory building regulations, it is far easier if consideration is given to the DVSA-mandated standards at the building design stage. Not only can this help with conformity, but it can also help with workshop utilisation.”

In Tonbridge, the Tecalemit Garage Equipment team has worked with the site developers, clients and building contractors to create a multi-bay vehicle workshop. The first stage considered the many available workshop layout options presented with a new build workshop.

Working with the blank canvass of a new build workshop unit might sound simple. Still, with a Tecalemit Class 4 MOT bay, four Tecalemit SF/9010/H 2-Post Lifts and a Tecalemit SF/9008/4 wheel alignment lift, together with offices and reception areas, there is an unlimited number of layout options to be whittled down to the final solution.

By carefully considering the DVSA’s MOT bay specifications, there are options to use some of the building’s external space as part of the brake test standing area. Whilst this requires the workshop door to be open during part of the test, it reduces the space needed within the building to accommodate the remainder of the MOT test lane. A recessed vehicle MOT lift also reduces the overall size of the footprint required for testing.

The complete implementation plan differs somewhat from the MOT bay installation in an existing workshop. In a current workshop, it is pretty easy to use line marking paint to mark the floor in the area of the proposed MOT location. In a new build situation, where no building exists, there is no floor to mark. Tecalemit can work with the architect’s drawings and overlay the MOT layout concept, followed by the subsequent floor recesses for the Tecalemit DE/9419 brake tester and the SF/9254 MOT lift.

This is an essential part of the pre-construction process. A lot of concrete goes into a floor of 350 square meters. All cable ducting for the power and communication cables must be accurately specified. None of this is a problem for our workshop design team, who almost take for granted the need to “measure at least twice, pour the floor once”. It is essential to obtain an Agreement In Principle (AIP) from the DVSA before the ‘pour of the floor’, as once the floor is cast in stone, subsequent alterations cause time delays and unnecessary additional costs. With the overall workshop layout approved by the client, the specific layout dimensions and DVSA requirements can be incorporated into a layout drawing to support the client’s DVSA VT01 application to create MOT testing at the new workshop location. All of this has been undertaken in parallel with the base site preparation.

Eventually, the civil work is completed after all the planning and building construction work commences. A thoroughly prepared workshop floor with accurate equipment recesses and ducting emerges from the hardcore to look like it has always been there.

With the concrete set, workshop equipment can be delivered to allow our engineering team to commence with the installation. With a national team of over sixty engineers, seeing a brace of Tecalemit vans in the car park is a regular sight, and many hands do light work. With six vehicle lifts and a complete MOT bay, many engineers must complete site installation within a few days. At this stage, the overall project for the client will have been underway for almost a year, so there is a requirement to get the installation undertaken without further delays to get the workshop operational and generate sales revenue for the client.

Call Tecalemit on 01752 219111 to access the knowledge and skills of Ian Blackett and his Workshop Specialist Colleagues.