It was December 2019, and the Isle of Man Test Centre required Emissions Test equipment for Petrol and Diesel vehicles. The requirement for Emissions testing on the island differed from mainland UK. Visual emission checks were being undertaken at the roadside, but they were limited to the identification of any smoke, visible vapour, toxic gases, or oily substances being emitted from a vehicle to an excessive extent. Whilst the process for emissions testing on the island differed from the UK mainland, the Tecalemit MDS combined unit suited the future requirements of the IoM Test Centre exceptionally well. The Tecalemit MDS has one of the highest specification gas benches on the market. This means that it measures down to OIML Class 00, two classes higher than required under current DVSA legislation. Additionally, the Tecalemit MDS only requires a single annual calibration for both Petrol and Diesel. In an offshore location such as the Isle of Man, this only means a single calibration visit, which delivers significant cost savings for the operator compared to other machines on the market.

The product enquiry was passed to Tecalemit’s team of MOT Equipment Specialists, a team that collectively possesses over 100 years of specialist workshop design throughout the UK. Tecalemit’s expertise covers a full range of workshop equipment, from car and commercial vehicle lifts, inspection pits, brake testers and the wider workshop umbilical equipment such as oil, air and water. Whist in discussion with the team at the IoM Test Centre, it became evident that whilst the initial need was for Emissions Testers, there were emerging plans to build a complete new roadworthiness test centre.

The specific requirements for testing on the IoM differ slightly from both DVSA Class IV, VII and CV Authorised Testing Facilities (ATF), so a comprehensive understanding of Tecalemit equipment specifications was required. This presented little in the way of a challenge for Tecalemit’s Equipment Specialists, who have created many Class IV, VII and Commercial Vehicle testing workshops and can switch from Passenger Car through Light Commercial Vehicle to Heavy Commercial Vehicle equipment.

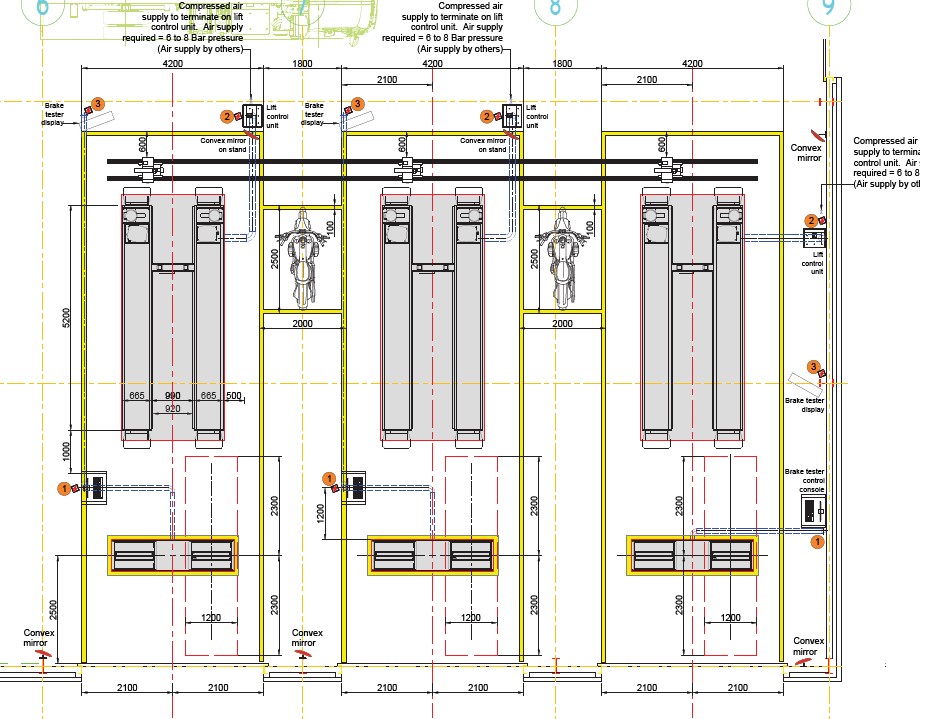

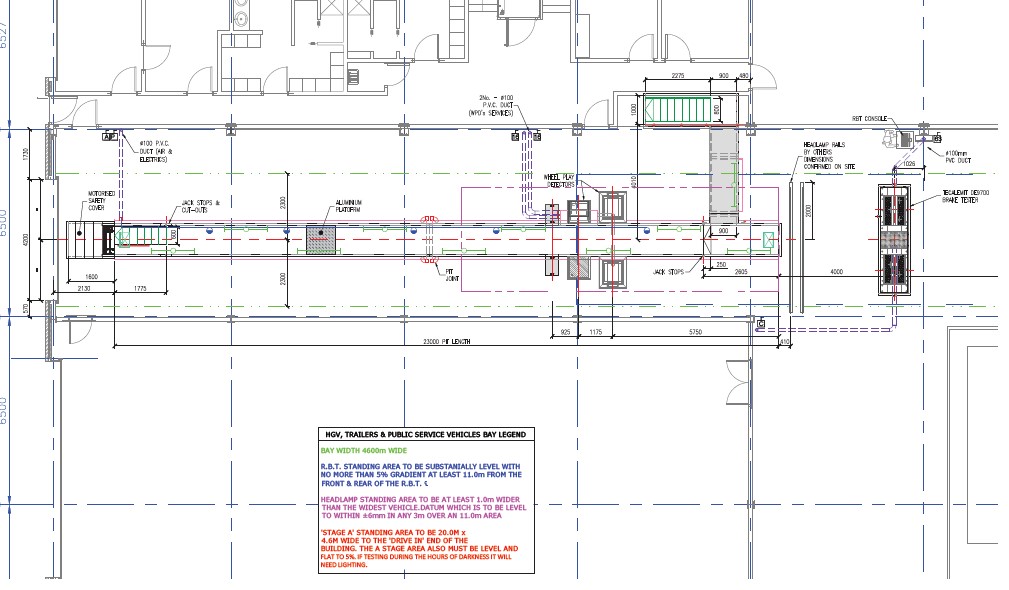

Tecalemit’s expertise in workshop design extends to cover more than just the Tecalemit equipment that needs to be installed. The team has extensive workshop design experience and is capable of working with architects’ drawings as a base for equipment plans. While discussing the proposed building size and configuration, it was Tecalemit’s opinion that the initial concept design layout for workshop doors was adding considerable costs to the specification of the building. Tecalemit created an alternative workshop layout design that enabled the internal space to be used in such a manner that the requirement for doors could be reduced by positioning them on different sides of the building. This also achieved a reduction in workshop size and cost without compromising the utility of the space, which relieved budgetary pressure on the project team regarding the internal equipment specification.

The equipment requirements for these new workshops were significant. A Commercial Vehicle pit complete with Tecalemit DE/7353 Axle Play Detectors. A Tecalemit DE/9700 CV Brake Tester. Three Tecalemit SF/9064/6/EV MOT 5T Scissor Lifts complete with rear slip plates and integral secondary lifting tables. Three Tecalemit DE/9719 Brake Testers for Class III, IV, VL & VII. Two of the brake testers were also equipped with Class I & II Motorcycle Adaptors. Four Tecalemit DE/7588 Headlamp Testers. A Tecalemit SF/9084 4-Post Service Lift completed the suite of equipment.

With the proposed design layout being approved and the equipment specifications concluded, it remained only to schedule the appropriate work. The challenges associated with working in an offshore location were further exasperated by the changing Coronavirus restrictions that existed on the Isle of Man at the time. There was a need for some precise activity scheduling to ensure the equipment installation was well sequenced.

The engineering team on the project was comprised of numerous Tecalemit engineers together with technicians from the civil contractors. All of this needed to be scheduled to pinpoint accuracy to ensure activity was coordinated in a phased delivery approach. With an offshore location, it is not so easy to parachute in extra engineer resources at the drop of a hat. This necessitated an understanding of the full range of Tecalemit engineer skills required for the entire suite of equipment.

With all of the equipment installed, the new Vehicle Testing Centre looks fantastic, providing a comprehensive, efficient and modern vehicle testing facility for cars, motorcycles, LCV and HGV vehicles.

Call Tecalemit on 01752 219111 to understand how the team can help turn your workshop requirements into reality.