It was back in the late 1980s that Gordon Winter at Coalville MOT Centre installed a Tecalemit DE/7200 MOT Roller Brake Tester and Tecalemit Headlamp Beam Tester to commence Class 4 MOT testing. Since then, over 12,500 vehicles have had their MOT brake performance tested on the Tecalemit equipment, which has performed superbly over the years.

Fast forward thirty-plus years, Gordon and Caroline at Coalville MOT wanted to increase their testing capability to include Class 7 vehicles. Several of their customers operate vehicles in the Class 7 category, and they were keen to keep the revenue in-house. Not only that, but it is operationally inconvenient and time-consuming to move vehicles back and forth to their nearest Class 7 MOT test facility.

Gordon and Caroline contacted Gary Clark at Shepshed Auto Spares (SAS), an Alliance Automotive Group company and a leading distributor for Tecalemit Garage Equipment. Gary at SAS has been dealing with the capital equipment requirements of his customers for many years. During this time, Gary has developed a comprehensive knowledge of DVSA-mandated MOT bay dimensions.

Gary works closely with Tecalemit’s Area MOT Specialist for the Midlands, and together they have over 50 years of experience. Tecalemit has designed car and commercial MOT testing facilities all over the UK, and there are little by the way of challenges that we have not come across over the years.

This experience is invaluable when dealing with a site such as Coalville MOT Centre. While they were originally granted DVSA approval back in the late 1980s for Class IV, the size of the MOT bay created some challenges to gain DVSA approval to move up to Class 7 testing.

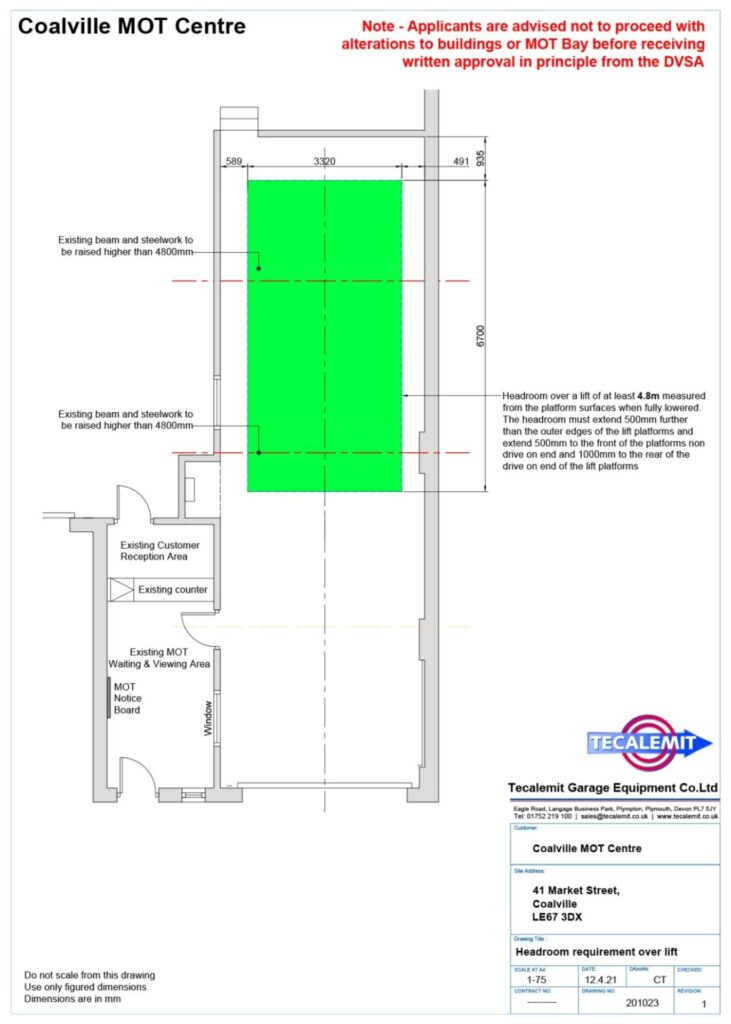

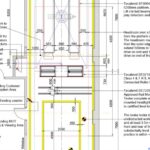

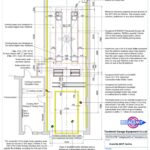

The first challenge was headroom, with Class 7 bays requiring an additional metre of height over Class 4 bay dimensions, and the issue was immediately visible. The workshop had two ceiling support joists that did not meet the minimum Class 7 regulations. These would need modifying to create the additional headroom required above the vehicle lift.

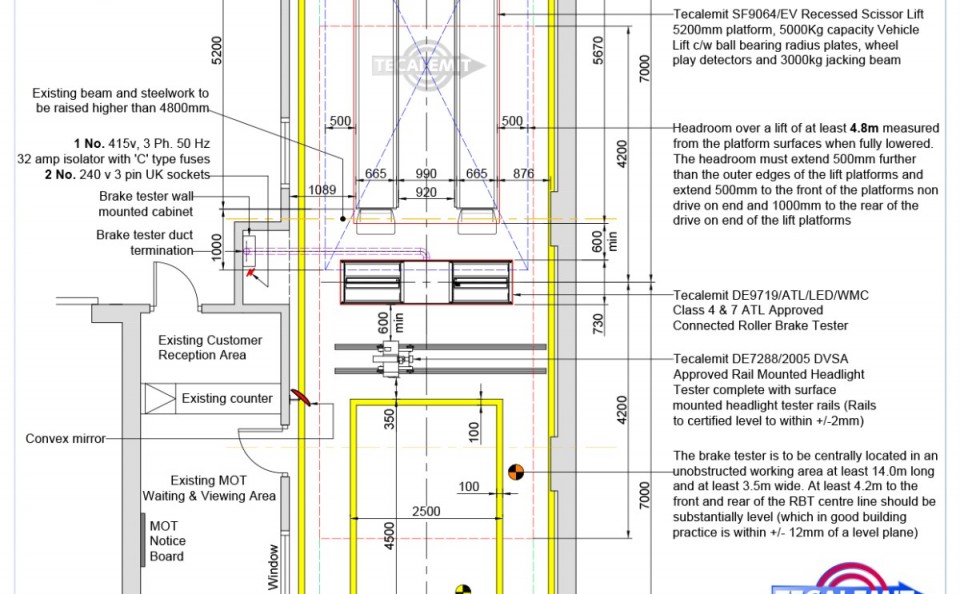

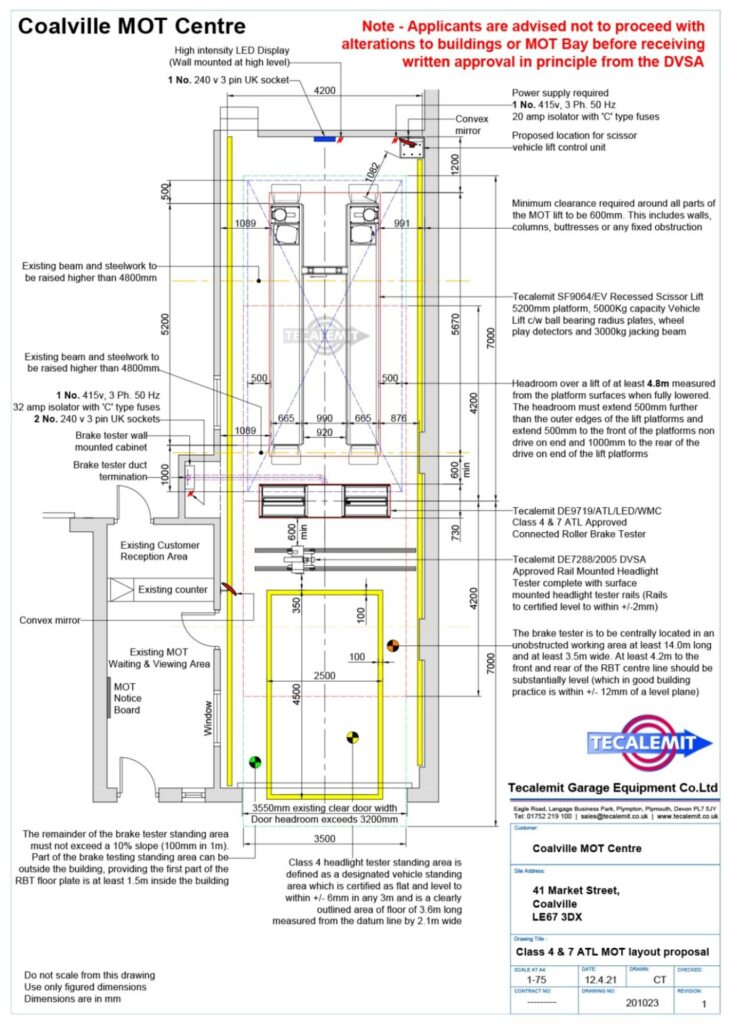

There was also a bay width issue that needed to be addressed. Their original MOT bay utilised a narrower, 4.3m long 4-post lift which needed to be changed to a Class 7 capacity lift. The team at Coalville MOT needed a lift with the necessary capacity to accommodate the increased weight and dimensions of Class 7 vehicles. This created the second challenge as the width of a Class 7 4-post lift is wider, starting at 3230mm outer post to outer post. Plus, the DVSA regulations require 600mm between the post and the wall to comply with health and safety regulations.

This meant that a 4-post Class 7 lift could not be accommodated without major structural alteration to the walls. As an operational Class 4 bay, and whilst anything is possible given enough time and money, it is understandable that Gordon and Caroline needed to keep the downtime of their MOT bay to a minimum. We presented an option using one of Tecalemit’s space-saving scissor lifts, the SF/9064/EV. The Tecalemit range of scissor lifts includes options for Class 4 & 7 MOT testing, providing versatile solutions for workshops with limited space available.

So with the first two challenges out of the way, at least from a test bay design perspective, the next would be the replacement roller brake tester. Their faithful Tecalemit DE/7200 Class 4 machine would eventually run its final few tests, after over thirty years of reliable service, to be updated to the latest specification Tecalemit DE/9719 Automated Test Lane (ATL) brake tester, complete with the current DVSA connected equipment specification.

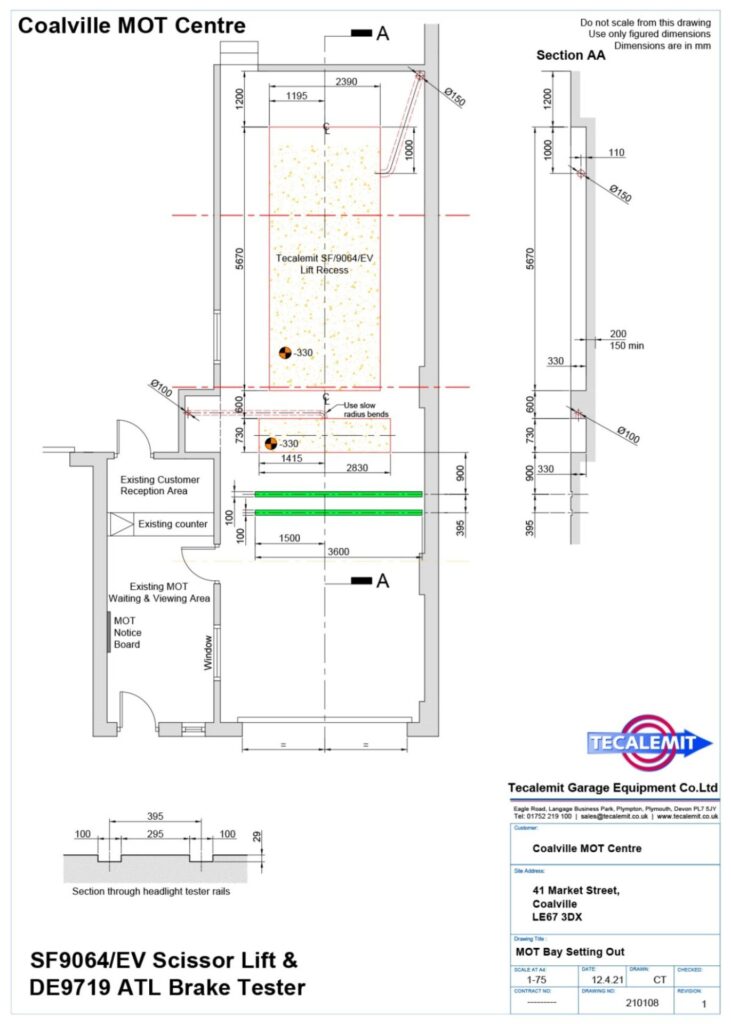

To go with the new space-saving layout, a DE/7288 Headlamp Beam Tester was positioned in a drive-over configuration on approach to the MOT bay. Now, we just needed to produce the ‘scaled layout’ and ‘set out’ drawings to assist with the completion of the DVSA VT01 application form.

With the ‘Agreement In Principle’ granted by the DVSA, Gordon and Caroline could now schedule the project’s civil work. This was a substantial quantity of work covering the recesses for the new scissor lift and brake tester, as well as the recessed headlamp beam tester rails. As with all projects of this nature, the marking out of the floor is a crucial stage. As ever, the phrase “measure twice, cut once” became essential as the excavation work was followed by pouring several tonnes of concrete.

The Tecalemit project team worked with the appointed builder, ensuring they had a thorough understanding of the dimensions and level requirements. The DVSA stipulates a level requirement of +/-6mm for the headlamp test standing area and +/-12mm for the brake test standing area. In this instance, the headlamp test standing area overlapped the brake test standing area, so a tighter tolerance had to be applied. The builder must understand the requirements and specifications; project management by Tecalemit’s area MOT specialist ensures this happens. The site’s level certificate is one of the key elements in obtaining the final sign-off from the DVSA, so it is in the interest of all stakeholders to ensure that this requirement is met during the process of getting the site ready for the equipment installation.

We wish Gordon, Caroline and their team every success with their new Class 7 MOT facility.

To understand how you can access the experience and expertise of the Tecalemit MOT specialists, along with the Tecalemit Garage Equipment installation and support teams, call us on 01752 219 111 or email [email protected]