It was January 2022 when Burchin Tepe decided to create his own MOT and service centre. A bold move for any vehicle technician to make but with fifteen years of experience behind him, Burchin was confident in his skills and abilities.

Searching for suitable premises commenced, and Burchin found a dilapidated vehicle repair workshop in Waltham Abbey. The premises appeared to be a promising proposition, but there were challenges ahead. The building had once housed a Class 4 MOT facility many years ago. There was a brick-built vehicle inspection pit with a makeshift ladder for access and an old floor recess for a Roller Brake Tester.

Burchin needed to achieve his goal on a tight budget. After speaking with a few alleged specialists, it had been indicated to Burchin that it couldn’t be done. Mustafa Ugan at GSF, Tecalemit’s equipment distributor, suggested involving Bernard Gravillis. Bernard has worked with DVSA regulations and minimum dimensions for over twenty years and has developed an excellent understanding of the interrelationship between the various DVSA-mandated standards.

An existing brick-built pit in the floor required precise modifications to ensure it would comply with current DVSA regulations. The makeshift ladder would need to be replaced with appropriate stairs that would satisfy DVSA and HSE requirements. This was further complicated by the need to increase the distance between the roller brake tester and the drive on the end of the inspection pit to meet the latest 600mm DVSA requirement. If the phrase ‘measure twice, construct once’ was ever applicable, this was no exception. Bernard was working to millimetre accuracy when forming his proposals.

The ingenuity didn’t end there. Bernard proposed a fabricated structure to increase the distance between the roller brake tester and the inspection pit by producing a purposely designed steel enclosure. The inspection pit also had a history of occasional water ingress, so the enclosure would double up as a pump housing. With the drainage also concealed, the ability to drain the water is completely hidden whilst ensuring the DVSA minimum pit dimensions are maintained. The consequence of the modifications at one end of the pit had implications for the other end. Here the access stairs needed to fit within 900mm. A specific design would be required.

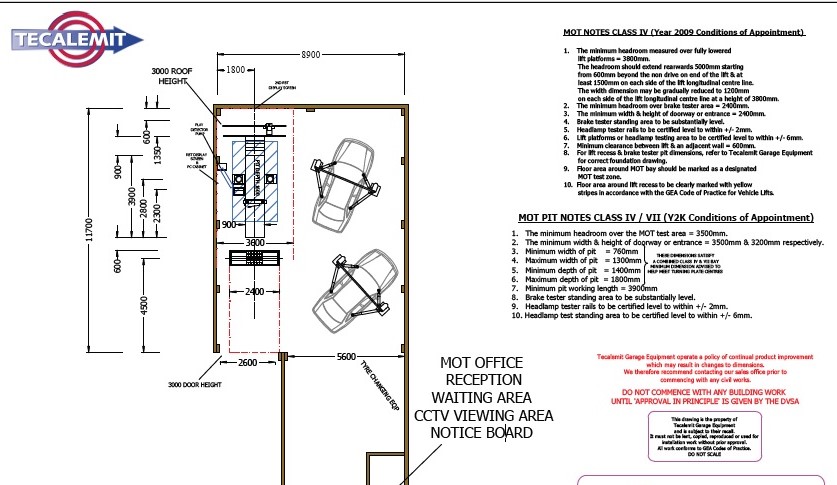

With concept design and construction proposals developed, the next step was to produce a layout drawing to demonstrate how the DVSA-mandated standards would be achieved. Burchin also required a pair of 2-post lifts for his new workshop. It had been suggested that these vehicle lifts would require positioning one in front of the other. That would have created the need to drive through the first lift to access the second. Bernard had an alternative layout suggestion that involved clear access to both lifts without compromising the MOT Bay dimensions. So with more precise measuring, the two service lifts were incorporated into the workshop layout drawing with clear access for both lifts.

With the drawing completed, Bernard helped Burchin with the completion of the DVSA VT01 application and supporting documentation. Agreement In Principle (AIP) was received on the first application, enabling the precise construction work to commence.

Specific measurements were given to a local steel fabricator who manufactured the pit access stairs to millimetre-perfect dimensions. The recess for the Roller Brake Tester was modified to accommodate the latest Tecalemit DE/9419 Class 4 ATL DVSA connected unit. The floor adjacent to the Vehicle Inspection Pit was modified to take a new set of Tecalemit OA/60354 floor radius plates and a Tecalemit DE/7361 single plate play detector. A Tecalemit DE/7288/2005 headlamp beam tester and an Autotest combined emission tester, mirror kit and OA/60415 ancillary package completed the suite of one-person MOT testing equipment.

Accompanying the Tecalemit equipment with a five-year warranty, calibration, and service contract enabled Burchin to take advantage of additional discounts on the Tecalemit 2-post lifts and a Tiro tyre changer and wheel balancer package.

With all the civil works completed and the equipment installed, DVSA sign-off was achieved within four months of the initial site surveys. The finished facility looks fantastic, and Tecalemit wishes Burchin every success with his new venture, BNT Motor Works, Nazeing, and Waltham Abbey.

For more information, check out BNT Motor Works on Facebook

To contact Bernard or your local Tecalemit MOT specialists, call us on 01752 219111